us low speed bumper impact test|bumper crash test procedure : purchaser Impact Speed Measurement Impact speed is measured using an optical speed sensor mounted on the side of the vehicle and aimed downward to detect reflective tape strips on the crash hall . WEB19. 23. 24. 25. Lotofácil - Concurso 3032. Data do Sorteio: 19/02/2024. 01. 02. 04. 06. 07. 08. 10. 11. 14. 15. 17. 18. 19. 23. 24. Lotofácil - Concurso 3031. Data do Sorteio: .

{plog:ftitle_list}

WEBCredalitas sl es una sociedad limitada que ofrece servicios de consultoría, soporte, desarrollo y venta de productos y sistemas de tecnología de la información. Consulte su .

rcar dynamic bumper test

The RCAR Bumper Test encourages vehicle manufacturers to produce effective bumper systems that feature tall energy absorbing beams and crash boxes that are fitted at common heights and can effectively protect the vehicle in low speed crashes.The assessment includes an estimation of the vehicle damage (physical damage .Goals of new program. General: Reduce the real-world property damage costs associated with low-speed crashes by promoting stability, compatibility and energy absorption. Front tests: .Information and Cost Savings Act. P581 specifies the following requirements for low speed vehicle impacts: A. Prohibits damage to the vehicle surfaces B. Incorporates the safety .

Impact Speed Measurement Impact speed is measured using an optical speed sensor mounted on the side of the vehicle and aimed downward to detect reflective tape strips on the crash hall .Four different low-speed crash tests, at a nominal 5 mi/h (8 km/h) impact speed, are performed on each vehicle model: front into full-width flat barrier, rear into full-width flat barrier, right front .This standard establishes requirements for the impact resistance of vehicles in low speed front and rear collisions. § 581.2 Purpose. The purpose of this standard is to reduce physical .

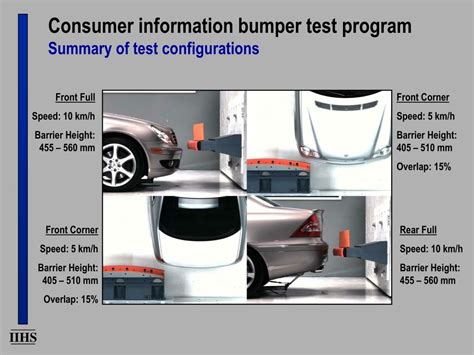

The assessment includes an estimation of the vehicle damage (physical damage and repair cost) in two impacts: A 15 km/h frontal impact into a rigid barrier and a rigid-faced mobile barrier .The RCAR Damageability Working Group establishes and maintains standards for evaluating the damageability of vehicles in low speed crashes where the structure of the vehicle may be .The Insurance Institute for Highway Safety (IIHS) began testing bumpers by rolling cars into bumper barriers at a speed between 5 and 8 mph. The damage was photographed, videotaped, and assessed by two independent parties. 49 CFR Part 581, “The bumper standard,” prescribes performance requirements for passenger cars in low-speed front and rear collisions. It applies to front and rear bumpers .

Low-Speed Impact Testing of Pickup Truck Bumpers 2001-01-0893 The purpose of this paper was to compare the damage to pickup truck bumpers produced by vehicle-to-barrier and vehicle-to-vehicle collisions of a similar severity, in order to determine whether vehicle-to-barrier tests can serve as surrogates for vehicle-to-vehicle tests in accident .vehicles in low speed crashes. 2. Stability – vehicle bumpers need to be tall and wide enough to remain engaged with the bumpers of other vehicles despite vehicle motion due to loading, braking, etc. 3. Energy-absorption – vehicle bumpers should absorb low speed crash energy without damage to other parts of the vehicle. For model year 1979, the standard required that there be no damage to safety-related parts and exterior surfaces not involving the bumper system (e.g., sheet metal; lamps; and fuel, exhaust and cooling systems) with damage to the face bar and its fasteners at impact test speed of 5 mph front and rear impacts with barrier and pendulum; 3 mph .

Impact accelerations for '84 Audi 4000S (piston bumper) rearended by '87 Hyundai Excel (foam bumper). Curves normalized to 7.5 mph impact velocity. In this research, a low-speed impact numerical simulation has been performed on a 6063-T6 Aluminum alloy bumper welded by MIEA technique using ANSYS® LS-DYNA® Workbench™ 19.2, according to the .

Side impact test program rating guidelines April 2006; Guidelines for rating injury . Bumper testing. Test protocol. Version VIII, September 2010; . Version I, November 1996; Summary of IIHS low-speed crash test program. May 2006; Dummy positioning. Test protocol: Dummy seating procedure for rear outboard positions — procedure for .

%PDF-1.5 %µµµµ 1 0 obj >>> endobj 2 0 obj > endobj 3 0 obj >/ExtGState >/ProcSet[/PDF/Text/ImageB/ImageC/ImageI] >>/Annots[ 8 0 R 15 0 R 16 0 R] /MediaBox[ 0 0 .

LABORATORY TEST PROCEDURE FOR REGULATION PART 581 Bumper Standard SAFETY ASSURANCE . P581 specifies the following requirements for low speed vehicle impacts: . after September 1, 1979 D. Limits the impact force levels for pendulum impacts to reduce the frequency of override and under ride. 3 3. SECURITY

We can evaluate low-speed impact cases. These can be challenging, but our approach has proven successful. . (IIHS) began testing bumpers by rolling cars into bumper barriers at a speed between 5 and 8 mph. The damage was photographed, videotaped, and assessed by two independent parties. . We also use third-party cookies that help us analyze . Low-Speed Impact Bumper System Test Procedure for Passenger Vehicles(STABILIZED Oct 2019) J2319_201910 The scope of this SAE Recommended Practice is restricted to the testing of original equipment on passenger vehicles and to provide for a uniform industry test procedure.To test the resiliency of its bumper during low-speed collisions, a 1 000-kg automobile is driven into a brick wall. The cars bumper behaves like a spring with a force constant 5.00 $$\times 10^6$$ N/m and compresses 3.16 cm as the car is brought to rest.To test the resiliency of its bumper during low-speed collisions, a 2 760-kg automobile is driven into a brick wall. The car's bumper behaves like a spring with a force constant 4.00 10 6 N/m and compresses 3.38 cm as the car is brought to rest. What was the speed of the car before impact, assuming no mechanical energy is transformed or transferred away during impact with the wall?

RCAR Low-speed structural crash test protocol 8 / 18 Issue 2.3 5.0 TEST FACILITY AND TEST VEHICLE PREPARATION - REAR IMPACT The test facility and preparation of the test vehicle shall be similar to that described for the front impact (section 4.1 and 4.3), with the following additions/exceptions: 5.1 Barrier set up and position

rcar bumper testing

During accidents under low speed impact the bumper beam absorbs the kinetic energy by deflection and under high speed the bumper beam absorbs energy by deformation [5]. Analysis of low speed impact using bumper beam of different material is also performed by many authors, but the concept of lining up of front metal bumper with suitable stiff .Fig. 1 shows the schematic diagram of a low-speed impact test [2]. According to these conditions, the car should be placed on a flat surface with released gear and brake and impacted both from .

To test the resiliency of its bumper during low-speed collisions, a 1 520-kg automobile is driven into a brick wall. The car's bumper behaves like a spring with a force constant 4.00 x io6 N/m and compresses 3.38 cm as the car is brought to rest.Chrome plated front bumper on a 1958 Ford Taunus Rear bumper with integrated tail lamps and a rubber-faced guard on a 1970 AMC Ambassador. A bumper is a structure attached to or integrated with the front and rear ends of a motor vehicle, to absorb impact in a minor collision, ideally minimizing repair costs. [1] Stiff metal bumpers appeared on automobiles as early as .To test the resiliency of its bumper during low-speed collisions, a 4 550-kg automobile is driven into a brick wall. The car's bumper behaves like a spring with a force constant 4.00 10 6 N/m and compresses 3.26 cm as the car is brought to rest. What was the speed of the car before impact, assuming no mechanical energy is transformed or transferred away during impact with the wall? It is found that in the dynamic three-point bending and sled low-speed impact, the bumper beam absorbs most of the kinetic energy; while the energy absorbing box does this in the 40% offset crash. The ultimate internal energy of sled low-speed impact, three-point bending and 40% offset crash are 2374.0 J, 8226.5 J and 1721.0 J, respectively.

The Bumper Pendulum (BP) is intended for low-speed bumper impact testing according to worldwide regulations like ECE R42 and FMVSS Part 581. The BP consists of a large frame that supports a swinging mass via a parallelogram linkage. The scope of the present work involves analyzing the structural behavior of car bumpers under low-speed impacts, focusing on bumper design and material selection. . The stress and displacement induced by the low-speed (30 kmph) Impact test on the five different designs were investigated. . The SMC performs best for us at a speed of 20 km/h .Low-Speed Structural Crash Test Protocol (Issue 2.4) Bumper Test Procedure (Version 2.3) July 2023 The German Insurance Group Rating Procedure is currently being revised by the German Insurers’ Association GDV and therefore not available here until further notice

impact. Schematic diagram of a low-speed impact test is shown in the Fig. 2. Figure. 2 Low-Speed Impact test Since the impact between the front bumper and an impactor is nonlinear and transient analysis are involved, this phenomenon can be very complicated in low-speed crashes. Therefore, the automobile In 2006, the Insurance Institute for Highway Safety (IIHS) released a new Low Speed Bumper Test Protocol for passenger cars1. The new test protocol included the development of a deformable barrier that the vehicle would impact at low speeds. IIHS positioned the new barrier to improve correlation toTo test the resiliency of its bumper during low-speed collisions, a 1 060-kg automobile is driven into a brick wall. The car's bumper behaves like a spring with a force constant 6.00 10 6 N/m and compresses 3.5 cm as the car is brought to rest. What was the speed of the car before impact, assuming no mechanical energy is transformed or transferred away during impact with the wall?

speed into the barrier at its normal running attitude. Impact Speed Measurement Impact speed is measured using an optical speed sensor mounted on the side of the vehicle and aimed downward to detect reflective tape strips on the crash hall floor. The leading edges of the strips are spaced 456 mm apart.

The numerical simulations are obtained for low-speed pendulum impact test to prove the crashworthiness of the proposed bumper beams. . bumper crash simulation data for US, Federal regulation .

wholesale Bottle Cap Torque Tester

A pandemia do novo coronavírus interrompeu as produções de filmes pornográficos.O isolamento para reduzir a transmissão do vírus, porém, gerou uma busca maior de .

us low speed bumper impact test|bumper crash test procedure